Forklift Truck Safety Signs-- Vital Visual Cautions for Work Environment Safety

Forklift Truck Safety Signs-- Vital Visual Cautions for Work Environment Safety

Blog Article

Forklift Safety And Security Signs: Vital Tips for Optimum Positioning and Presence

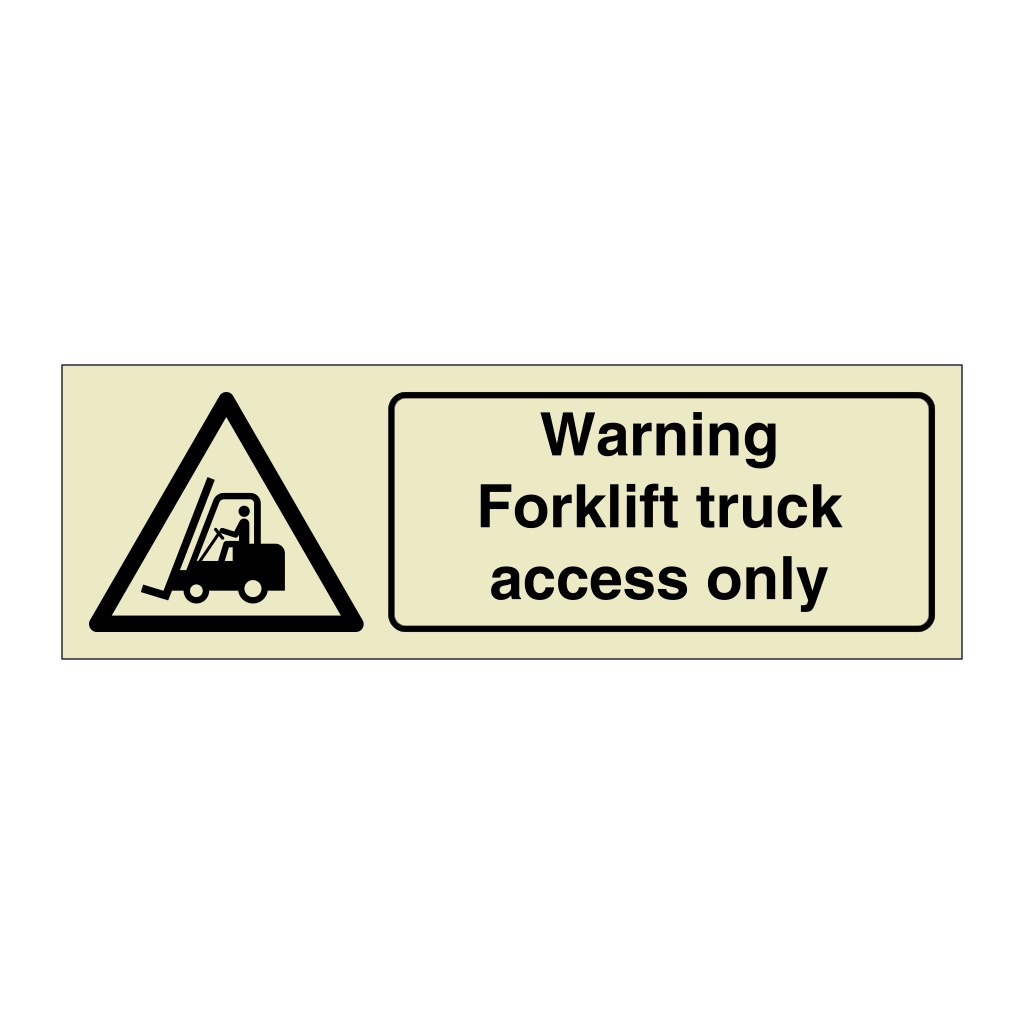

Making sure the optimal placement and presence of forklift security signs is critical in keeping a secure industrial environment. Positioning these signs at tactical areas such as access and leave factors of loading anchors, crucial facility intersections, and high-traffic storage locations can dramatically alleviate mishap threats. Mounting indicators at eye degree and angling them towards oncoming website traffic improves their effectiveness. In addition, utilizing long lasting materials and high-contrast designs makes certain durability and quality. Comprehending the subtleties of routine assessments and maintenance is similarly essential to promote their capability-- what vital steps should be taken to keep these essential safety and security devices?

Key Locations for Safety Indications

Proper positioning of forklift security indicators is vital for preserving a safe functioning environment. Additionally, positioning indicators near high-traffic storage space areas and blind areas can even more boost visibility and awareness.

Junctions within the center are an additional critical location where accidents can happen; for that reason, stop indicators and right of way indicators are crucial. In pedestrian-heavy areas, signs ought to inform both operators and pedestrians to the presence of forklifts, guaranteeing everyone stays vigilant.

Locations with high storage space racks and blind places position special challenges. forklift safety signs. Signage in these areas ought to caution drivers of restricted exposure and motivate the usage of watchmans or additional security measures. By concentrating on these key places, companies can create a safer, more efficient workplace for all

Elevation and Angle Considerations

When mounting forklift safety and security indications, taking into consideration the height and angle of placement is necessary to make certain maximum presence and efficiency. Correct height makes certain that operators and pedestrians can quickly see the signs without obstruction.

If an indicator is suggested to caution forklift drivers, it ought to be positioned directly in their field of view, preferably perpendicular to their direction of traveling. In locations with multiple checking out angles, consider utilizing double-sided signs or angled brackets to preserve presence from different instructions.

Additionally, ensuring that the indicators are not obstructed by various other objects, equipment, or shelving units is vital. Clear sightlines aid prevent accidents and improve overall security. By attentively thinking about height and angle, you can dramatically boost the performance of forklift safety and security signs, therefore cultivating a much safer workplace.

Signage Material and Longevity

Selecting the appropriate product for forklift safety and security indicators is crucial for guaranteeing their long over at this website life and efficiency. In environments where forklifts run, signs are usually subjected to extreme conditions, including physical effects, chemical spills, and differing temperatures. Picking long lasting materials like light weight aluminum, high-density polyethylene (HDPE), and polyvinyl chloride (PVC) can significantly enhance the indications' lifespan.

Light weight aluminum is a prominent selection as a result of its resistance to rust and deterioration, making it optimal for both indoor and outside setups. Furthermore, its light-weight nature helps with easy installation and repositioning. HDPE is an additional durable option, known for its outstanding resistance to chemicals and influence. It is especially ideal for settings where chemical exposure is widespread. PVC, on the other hand, supplies a great equilibrium in between resilience and cost-effectiveness, making it a typical choice for lots of commercial atmospheres.

Furthermore, the printing method made use of on these materials also contributes in longevity. UV-resistant inks and protective laminates help in protecting against look at this website fading and damage from sunlight and other environmental factors. Following these factors to consider ensures that forklift safety indications continue to be visible and clear over prolonged durations, thereby preserving a secure workplace.

Making Sure Sign Exposure

While picking durable products for forklift safety indications is essential, guaranteeing their visibility is equally essential for maintaining see this here a risk-free setting. Efficient presence can be accomplished through calculated positioning, correct illumination, and using high-contrast colors. Indicators ought to be positioned at eye degree and in locations where operators and pedestrians are more than likely to see them, such as at entrance points, junctions, and locations with high website traffic.

Proper lighting is vital to guarantee that indications are visible in all problems. Setting up appropriate lights in dimly lit areas or using reflective materials on indications can considerably improve presence.

Furthermore, avoiding visual mess around the indicators is important. Way too many check in one location can overwhelm and perplex individuals, decreasing the performance of each sign. Clear, concise messaging and ensuring signs are free from blockages such as equipment or storage space things will better improve their presence and effectiveness, contributing to a safer workplace atmosphere.

Routine Evaluation and Maintenance

Consistency is key to keeping the effectiveness of forklift safety indications, making regular inspection and maintenance essential. To make sure these signs continue to interact crucial details clearly, they need to be regularly looked for deterioration, fading, or obstruction. forklift safety signs. Gradually, direct exposure to the elements and functional tasks can weaken their presence and readability, threatening their function

Throughout evaluations, evaluate each sign's condition, ensuring message and icons continue to be clear and lively. Any indications revealing signs of damages or fading should be promptly replaced.

Final Thought

Proper placement and exposure of forklift safety indicators are essential in lessening work environment mishaps. Positioning indicators at crucial areas such as access and exit factors, facility intersections, and high-traffic storage space areas, while ensuring they are installed at eye level and tilted in the direction of oncoming website traffic, improves their effectiveness.

Report this page